What is Muting Sensor?

Muting sensors are a useful tool for ensuring operator safety in protected areas. They are used in conjunction with Safety Optical Sensors to detect the presence of an operator or pallet in a protected area. Their main use is to temporarily disable the protection function of the Safety Optical Sensor when specific conditions are met.

Muting Sensor Characteristics

When the Muting sensor is activated, it sends a signal to the Safety Optical Sensor to temporarily disable the protection function. Allows pallets to pass without triggering the safety stop function. This helps facilitate the safe movement of the operator within the protected area.

Optical sensors integrated with Muting sensors are capable of distinguishing between people and pallets. Only pallets are allowed to pass through the monitored area, and operator intrusion is prevented. “Muting” is only activated at an appropriate point of the machine cycle, i.e. only when there is no risk to the operator.

With this smart and advanced approach. You can ensure operator safety and optimize your production processes.

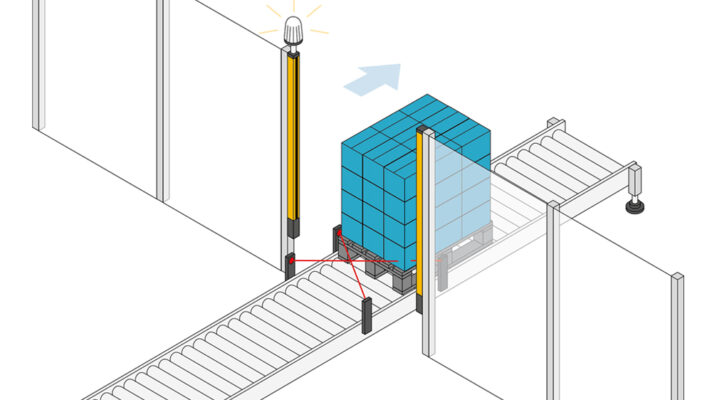

4 Stages In Sensor

Phase 1: Pallet in front of danger area – optical sensor bar is active – mute sensor is off.

Stage 2: Pallet goes to mute sensors 1 and 2 – optical sensor bar stops working – mute sensor works

Stage 3: Pallet goes to mute sensors 3 and 4 – optical sensor bar stops working – mute sensor works.

Stage 4: The muting process ends – the optical sensor works again.