Industrialization and economic development are increasing harmful emission, leading to environmental pollution. As a result, factories today face the challenge of effectively managing emissions to prevent environmental impact. Currently, emission standards have becom more stringent. Many existing dust filtration systems no longer meet the current standards. The need to adopt and implement appropriate emission control technologies has become inevitable to avoid undesirable consequences due to emissions and environmental standards.

Method of Emission Filtration

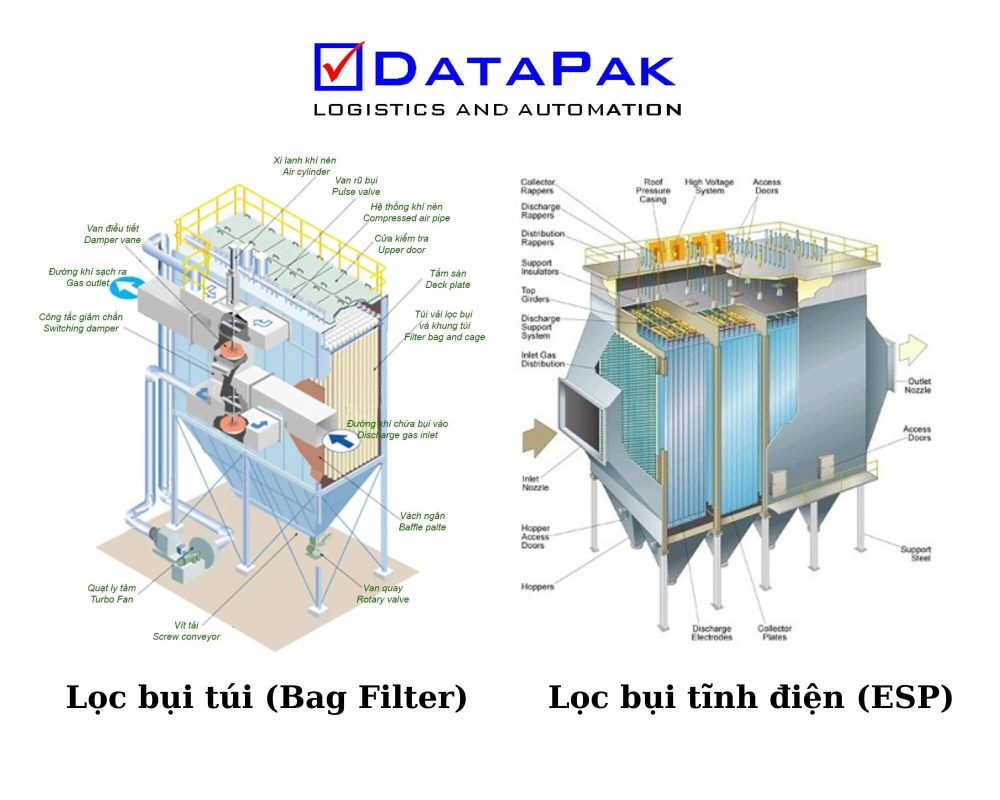

Bag Filters and Electrostatic Precipitators (ESP) are two of the most widely used emission control methods in factories.

However, there is a growing trend to use Bag Filters instead of Electrostatic Precipitators. The main reason is that Bag Filters offer higher filtration efficiency and are less affected by factors such as humidity, temperature, pressure, and the characteristics of the exhaust gases.

.

Principle of Exhaust Gas Filtration

Bag Filters operate on the principle of trapping dust and gases. The filter bags direct exhaust gases into them, retaining dust particles on their surface. Over time, the dust forms a filter layer capable of capturing fine particulate matter, including microscopic particles that can be inhalad by humans.

In contrast, Electrostatic Precipitators (ESP) work on the principle of ionization in a high-voltage electric field, typically around 100 kV. They separate smoke and dust from the air as it passes through the filter plates, which are charged with positive of negative ions, using the attraction of opposite charges. However, the efficiency of ESPs depends on several factors, including the size of the dust particles, the control equipment for the electric field, the air velocity, and the uniform distribution of air within the electric field.

Factors For Selecting a Dust Filtration System

Dust and Exhaust Gas Characteristics: The chemical composition of exhaust gases and dust directly influences the effectiveness of dust removal bases on the operating principle of the filtration equipment.

Exhaust Gas Flow Rate: This refers to the volume of air passing through a uni area per minute (m³/min/m²). The appropriate dust filltration system can be determined based on this flow rate.

Installation Area: For electrostatic precipitators (ESP), the system’s large size requires a spacious installation area. Additionally, a minimum of one meter of clear space in front of the machine is needed to ensure easy maintenance and cleaning of the filter plates.

In summary, choosing between these two types of filters depends on the specific needs of each enterprise and the characteristics of the exhaust gases. If you have any questions, don’t hesitate to contact Datapak for detailed advice and answers!

To ensure the dust filtration system operates efficiently and productively, a dust measurement device is crucial. These devices are installed within dut filtration systems. Currently, Sintrol is a leading brand providing high-quality dust measurement devices, trusted by many countries and major companies. If you have any questions about dust measurement, please contact Datapak for prompt assistance!

Hotline: 0795.40.60.80

Zalo: Datapak

Email: info@datapak.com.vn

Facebook:Vina DataPak JSC

Website: Datapak.com.vn

Linkedin: Datapak JSC

Shopee : https://shopee.vn/vinadatapak