With the continuous development of the economy, especially the heavy industry sector, air pollution is increasing. Environmental standards and regulations are becoming more stringent, requiring factories to take measures to reduce the amount of dust released into the environment, protect workers’ health, and ensure production efficiency. One of the key solutions is using dust filter systems, particularly bag filter monitoring to optimize performance and reduce maintenance costs.

Before delving into bag filter monitoring devices, let’s first understand what a dust filter system is and its types.

What is a Dust Filter System? How many types are there?

A dust filter system consists of devices or a combination of devices designed to remove dust, particles, or pollutants from airflow or exhaust gases, helping protect the environment and workers’ health. Some common types of dust filter systems include:

- Bag Filters: Use filter bags to capture dust particles.

- Electrostatic Precipitators (ESP): Use an electric field to separate dust from gas flow.

- Cyclone Filters: Utilize centrifugal force to separate larger dust particles.

- Wet Scrubbers: Use water to wash and absorb dust.

Among these dust filter systems, bag filters are an optimal and widely used solution in industries, particularly in factories with high filtering efficiency and precision requirements. So why are bag filters the preferred choice for factories?

Advantages, Disadvantages, and Process of Bag Filters

Next, let’s dive into the analysis of the advantages and disadvantages of bag filters, helping you better understand why this system is preferred and chosen in many industrial applications.

Advantages:

- High filtering efficiency (99 – 99.9%): Effectively removes most dust and pollutants.

- Handles various types of dust: Suitable for different dust types in industrial environments.

- Easy operation and maintenance: The system is easy to control and maintain regularly.

- Suitable for high airflow: Ideal for large capacity factories.

- Flexible in design and application: Can be adjusted to meet specific requirements.

- Reasonable investment and operating costs: Relatively low costs compared to other systems.

- Sustainable and environmentally friendly: Uses recyclable materials with minimal environmental impact.

Disadvantages:

- Requires large installation space: Bag filter systems need a wide area for installation.

- Filter bag replacement cost: After prolonged use, filter bags wear out and need replacement, which can be costly.

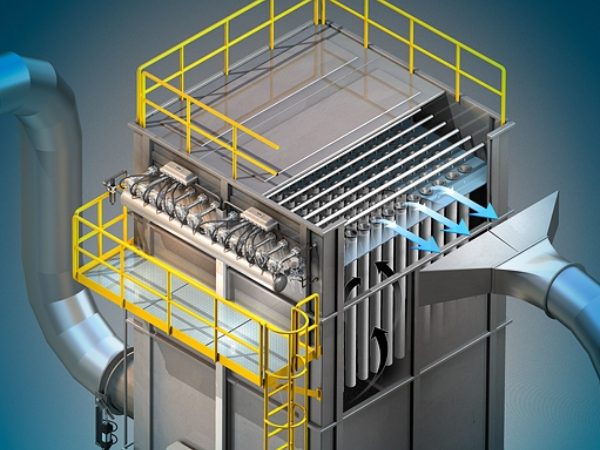

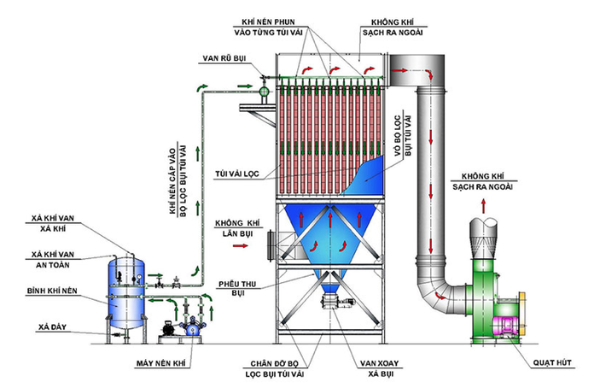

Bag Filter Process

Although the bag filter system has many advantages, the cost of replacing the filter bags remains a notable issue. One effective solution to optimize this cost is to use bag filter monitoring devices.

Benefits of Using Sintrol Bag Filter Monitoring Devices

Using bag filter monitoring devices brings many important benefits, including:

- Early detection of leaks: The monitoring device helps identify issues such as leaks, tears, or damage to the filter bags, reducing potential damage.

- Prolongs filter bag lifespan: Reduces unnecessary cleaning or filter bag replacement by monitoring the actual condition of the filter bags.

- Minimizes mechanical pressure and wear: Minimizes over-cleaning, preventing the filter bags from being worn out.

- Optimizes operational performance: The device helps maintain stable airflow and enhances the efficiency of the system.

- Cost savings: Reduces unnecessary filter bag replacements and maintenance time.

- Accurate measurement and reporting: Provides real-time data for better management and maintenance planning. The device can be integrated into central management systems to automate the monitoring process.

Conclusion

With its outstanding benefits, the Sintrol bag filter monitoring device is an effective solution to optimize performance and minimize unnecessary filter bag replacement costs. Choosing the right monitoring device for the factory’s needs is crucial.

Sintrol has developed different models to suit various applications and requirements.

Comparing the Differences in Sintrol Devices

Below is a comparison table of the differences between Sintrol bag filter monitoring device models:

Contact Datapak for Consultation

Datapak is the official distributor of Sintrol in Vietnam. We provide professional products and consulting services to meet the dust monitoring needs of factories in the woodworking industry and related sectors. If you are looking for an effective dust concentration monitoring solution for your factory, contact Datapak now for detailed consultation and the best support!

Contact us now for consultation, solution proposals, and fast quotes!

Address: 54Bis Nguyễn Bỉnh Khiêm, P.Đakao, Quận 1, TP.HCM.

Hotline: 0795.40.60.80

Zalo: Datapak

Email: info@datapak.com.vn

Facebook:Vina DataPak JSC

Website: Datapak.com.vn

Linkedin: Datapak JSC

Shopee : https://shopee.vn/vinadatapak